In compliance with EU personal data protection laws, we are committed to protecting and providing you with control over your personal data. We have updated and will regularly update our Privacy Policy to comply with this Personal Data Protection Act. Please refer to our latest version Privacy。

This website uses cookies to provide a better browsing experience. To find out more about how this site uses cookies please click here。

HOME>

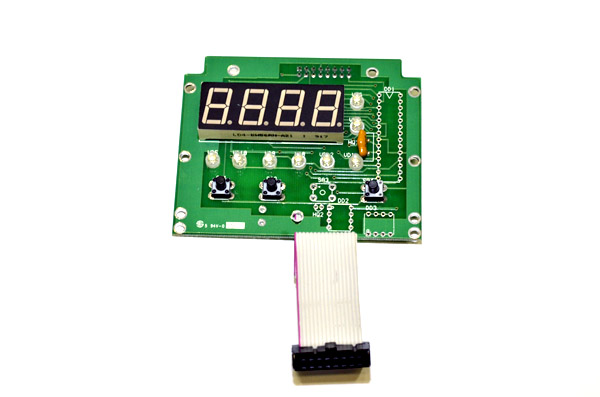

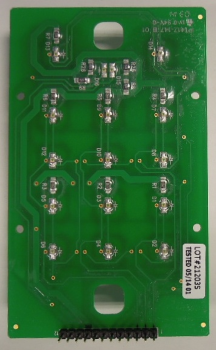

PRINTEC PRODUCES VARIOUS BASE CIRCUITS USED IN TODAYS HMI’S.

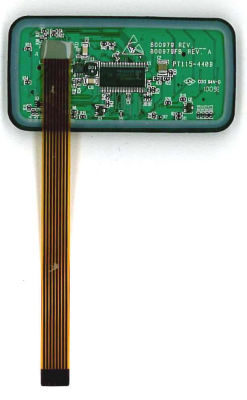

FPC is not a simple substitute for the wire but has a wide range of functions and uses. In the year of 2010, Printec began the FPC production with technical supports from USA and Japan. At Printec we offer a full range of specialized products: single and double sided flexible, multilayer flexible (up to 6 layers_), rigid flex circuit. We also offer artwork design and component assembly services for all these products.

About PCBA/FPCBA

We provide completely assembled and tested service. It includes surface mount assembly (SMT), through hole and mixed technology assembly, box build and system integration, prototypes and pre-production runs and specialized rework. The production department also features complete inspection and testing service including Microscope, AOI, 3D X-Ray, ICT, Functional, Flying Probe, Burn in, HiPot and Box built test and so on to meet manufacturing standards and to ensure overall customer satisfaction. Our building products experience range: industrial elevator system, digital video record (DVR) system, medical, computing, storage, instrumentation, traffic, industrial power, fire alarm, wireless communication, tele-communication, networking and house controller.

- PET Flex

- PET Through hole flex

- FPC flex

- PCBA

FPC is not a simple substitute for the wire but has a wide range of functions and uses. In the year of 2010, Printec began the FPC production with technical supports from USA and Japan. At Printec we offer a full range of specialized products: single and double sided flexible, multilayer flexible (up to 6 layers_), rigid flex circuit. We also offer artwork design and component assembly services for all these products.

About PCBA/FPCBA

We provide completely assembled and tested service. It includes surface mount assembly (SMT), through hole and mixed technology assembly, box build and system integration, prototypes and pre-production runs and specialized rework. The production department also features complete inspection and testing service including Microscope, AOI, 3D X-Ray, ICT, Functional, Flying Probe, Burn in, HiPot and Box built test and so on to meet manufacturing standards and to ensure overall customer satisfaction. Our building products experience range: industrial elevator system, digital video record (DVR) system, medical, computing, storage, instrumentation, traffic, industrial power, fire alarm, wireless communication, tele-communication, networking and house controller.